Paint-Masking Application

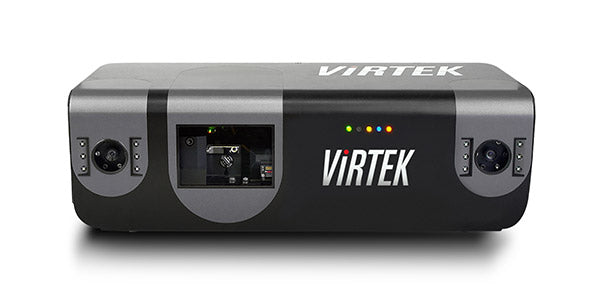

Virtek Vision International & Embraer Executive Jets Partnership

Taking a manual, complex and lengthy process and making it simple and cost-effective with an ROI in less than 6 months.

Embraer Executive Aircraft, Inc., located in Melbourne, Florida increased throughput and improved its paint-masking process by using Virtek Laser Projection Solutions. We are happy to have exceeded expectations with Embraer and wish them continued success in delivering the highest quality aircraft across their fleet.

#manufacturing #laser #engineer #vision #paintmasking #seethingsdifferently