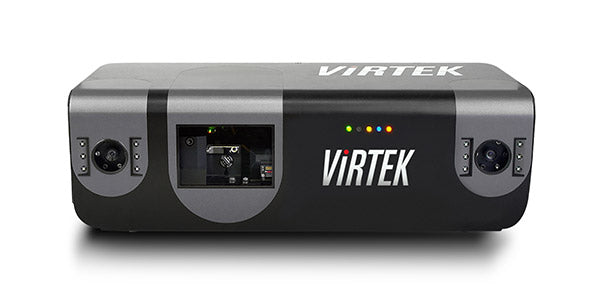

Komatsu was seeking to reduce errors in manufacturing, while at the same time increasing their throughput and efficiency to enable them to meet increased demand. They were using aluminum templates to guide workers in welding brackets, stand-offs and studs on large mining truck frames. These templates were costly to manufacture, design and redesign. Additionally, they were cumbersome, presenting Health and Safety risks, and taking up a lot of space to store. By implementing Virtek’s Iris Spatial Positioning System (SPS), Komatsu eliminated templates and significantly accelerated their assembly process, eliminating human errors and upholding quality because items are built exactly as designed.